Engage Energy and Industrial Consulting is teaming up with manufacturers in the United States and abroad to work towards a more circular economy. Together, we can make forge a more sustainable future that not only preserves American jobs, but also sustains our planet for generations. In this blog we are going to talk about the importance of implementing more ideas to mainstream the sustainability of a circular economy.

What is a Circular Economy?

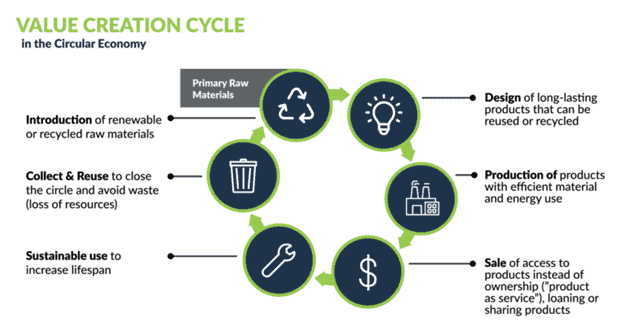

A circular economy is an economic system aimed at eliminating waste and the continual use of resources. It focuses on reusing, sharing, repairing, refurbishing, and recycling materials to create a closed-loop system, as opposed to the traditional linear economy of take-make-waste. The goal of a circular economy is to create a sustainable system where resources are used efficiently, and waste is minimized.

“The main reason for companies to opt for landfill or incineration is unfortunately down to both convenience and cost and, with carpets currently being difficult to recycle, manufacturing processes also have to change. Legislation is urgently required to increase the cost of both incineration and landfill which would then encourage recycling as the viable solution. Without the transparency needed to highlight these issues, improvements will take longer to implement.” –Robert Clarke, Forbes

How Does a Circular Economy Help Manufacturers?

Manufacturers today can benefit from a circular economy. Developing sustainable solutions both upstream and downstream, manufacturing in the United States and around the world can improve a sustainable world.

The Key Components of A Circular Economy:

- Closed-loop systems: These are systems in which waste from one process is used as input for another process, creating a continuous loop of resource use. For example, waste materials from a manufacturing process could be used as feedstock for another manufacturing process, rather than being discarded.

- Resource efficiency: In the circular economy, resources are used as efficiently as possible, with minimal waste and energy consumption. This can involve designing products for longevity and repairability, as well as using advanced technologies to recover and reuse materials.

- Collaboration: The circular economy requires collaboration among different sectors and stakeholders, including government, industry, and civil society. This can involve sharing resources and expertise, as well as developing new business models and regulations to support the transition to a circular economy.

- Circular business models: In the circular economy, business models are designed to keep resources in use for as long as possible, rather than disposing of them after a single use. This can include models such as product-as-a-service, where companies provide a product for a fee rather than selling it outright, and take-back programs, where companies accept used products for repair or recycling.

How Do We Add Value with a Circular Economy?

Cost savings: By reusing materials, manufacturers can reduce their dependence on virgin resources, which can lower production costs. In a recent report from the Ellen MacArthur Foundation there is a shift to a “nature-positive circular economy” to combat climate change and global challenges while driving economic growth in Europe.

Resource efficiency:

Adopting circular practices can help manufacturers optimize their use of resources and minimize waste, leading to higher resource efficiency. This requires that everyone in the circle look to those both up and down stream from them.

For instance. A greenhouse needs containers to start plants. The problem: most greenhouse containers on the market for growers are cheap plastic and not recyclable. So when a consumer buys the plants, they end up throwing the cheap plastic container into the trash. Millions of those containers make their way to the landfill.

In a circular economy, the container the plant came in, would be returnable to the grower. The grower can then reuse the container for the following season. Broken containers could be sent back to the manufacturer to be melted down into a new container. The loop for the container is closed making it a circular component in the loop. Less containers go to landfills.

The Role of Regulatory Compliance:

As governments and consumers push for sustainability, manufacturers that embrace circular economy. These principles can stay ahead of regulations and meet changing market demands.

For a circular economy to take hold policy makers on all levels of government must be involved in encouraging innovation. Some encouragement can include things like financial initiatives offered in the USA like the Bipartisan Infrastructure Law and the Inflation Reduction Act.

Today, it is important to align government policy with a more transitional circulatory path to sustain our environment. Manufacturing purchasing practices should transition to circularity through federal and state initiatives. Some examples of which are the Federal Buy Clean Initiative, the Federal-State Buy Clean Partnership and various state programs.

City and state level ordinances around deconstruction (as opposed to demolition), scrap and waste recovery, and adaptive reuse.

How A Circular Economy Helps Brand Reputation:

Embracing circular economy practices can enhance a manufacturer’s reputation as a sustainable and socially responsible company. This approach is appealing to environmentally conscious consumers.

A great example of a circular economy can be seen in manufacturers of glass bottles. Think of the milk industry. Prior to the introduction of plastic milk jugs. Manufacturers would make the bottles, dairy farmers would fill orders, and the milk was delivered. Once used, the old glass containers were picked up, they were taken back and washed and re-used. It was a closed circuit for the bottles. If a bottle was broken the glass was remelted into a new one. There are several smaller dairy brands that are bringing back this concept. It is being very well received by consumers. It is seen as elevated, smart, and environmentally responsible.

American manufacturers need to team up with suppliers and partner for circular projects like this. Imagine the impact. Sometimes, our predecessors got it right. Rethinking traditional manufacturing processes to fit within a circular model can drive innovation and create new business opportunities for manufacturers.

How Can Engage Energy & Industrial Consulting Help You?

For manufacturers today, the notion of the Circular Economy is being embraced as an economic model that prioritizes sustainability. While it continues to target cost reduction and minimizing waste. The team at Engage Energy & Industrial Consulting works with you to help keep products, materials, and resources. With a goal of creating a continuous loop of use by recycling, reusing, and remanufacturing. Through a circular economy, manufacturers reduce costs, and open new markets for by-products that were once disposed of. Contact Us today to learn more.